K-3 Fast Tooling

K-3 Fast Tooling

Many years of experience in R&D and migration to production have allowed Seipo to gain skills in prototyping tooling. We have invented our innovative K-3 tooling, a fast tooling solution that can save 30-50% lead time over the traditional tooling with the same cost. A trailblazing technology, the K-3 tools function similar to regular tools in all aspects but with normal output that is around 30,000 shots. They perfectly satisfy many applications in the early marketing stages. Our customers take advantage of K-3 tooling for its extraordinary speed, flexible modifications, and versatility in delivering products in the shortest time in a tough competitive field.

*K 3 tooling would not be suitable for over-molding and double/triple shot molding.

Many years of experience in R&D and migration to production have allowed Seipo to gain skills in prototyping tooling. We have invented our innovative K-3 tooling, a fast tooling solution that can save 30-50% lead time over the traditional tooling with the same cost. A trailblazing technology, the K-3 tools function similar to regular tools in all aspects but with normal output that is around 30,000 shots. They perfectly satisfy many applications in the early marketing stages. Our customers take advantage of K-3 tooling for its extraordinary speed, flexible modifications, and versatility in delivering products in the shortest time in a tough competitive field.

*K 3 tooling would not be suitable for over-molding and double/triple shot molding.

Injection molding special

Injection molding special

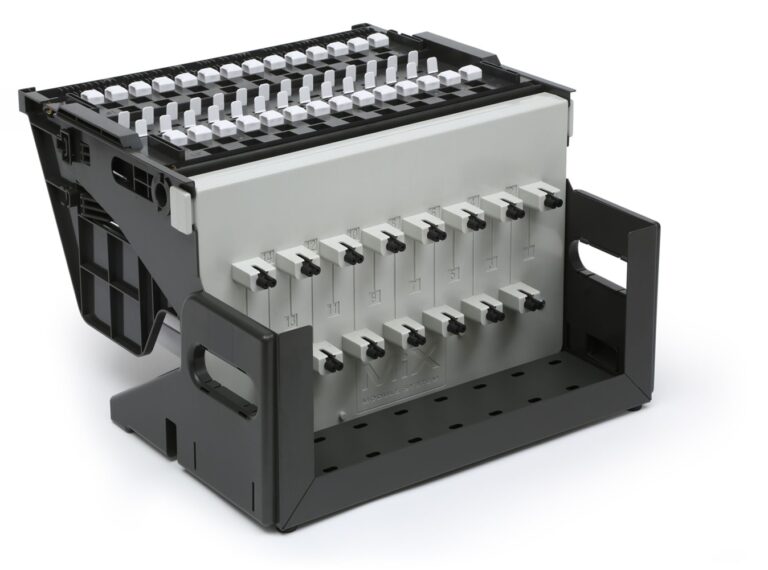

Seipo has the capability in various plastic molding including insert molding, over-molding, double and triple shot molding, and gas-assistant molding. Products as tiny as an earbud to an oversized plastic workstation panel may be produced from these various processes. Examples include FDA-certified medical components to the Apple iPad charging cart, which we can easily handle. The maximum capacity of the injection molding equipment is 3500 MT press.

Plastic Forming

Plastic Forming

Thermoforming, Hot plate welding, Plastic CNC, Plastic lamination