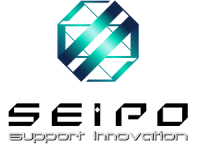

Die Casting

From rapid soft tools to hardfacing production tools, Seipo provides quick end-to-end solutions at different development stages for aluminum, zinc, and magnesium casting.

Leveraging the state-of-the-art CMC equipment, Seipo simply achieves both quick tool fabrication and precise machining for intricate parts in a shorter time. We’re specialized in thin and precision product design though our max capacity of the die casting is 2000MT press.

Certified to TS 16949, Seipo is savvy in making complex parts for automobiles and technologies. Responding to the market, we’ve also explored with success on color anodizing on die casting aluminum, open up new possibilities for cosmetic parts.

Final finishing along with its high standards is another area we have mastered. We can meet MIL spec standards in powder coating and chemical conversion.

Investment Casting

Stainless steel

Brass

Aluminum

Carbon steel

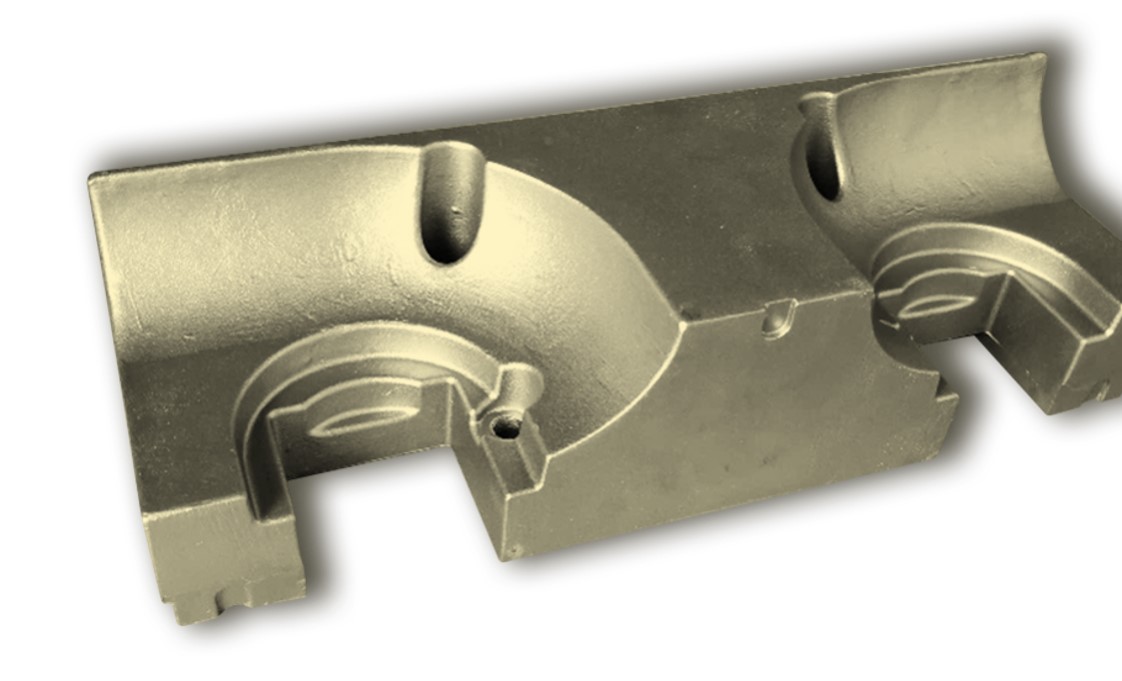

Metal Extrusion

Specialized in high precision and high cosmetic finishing extrusion. Our capabilities: Maximum length of part of 4500 mm and cross-section area of 465 mm, with maximum extrusion machine of 4000 MT.

Finish includes: anodizing, electrophoresis, powder coating, and fluorocarbon spraying.

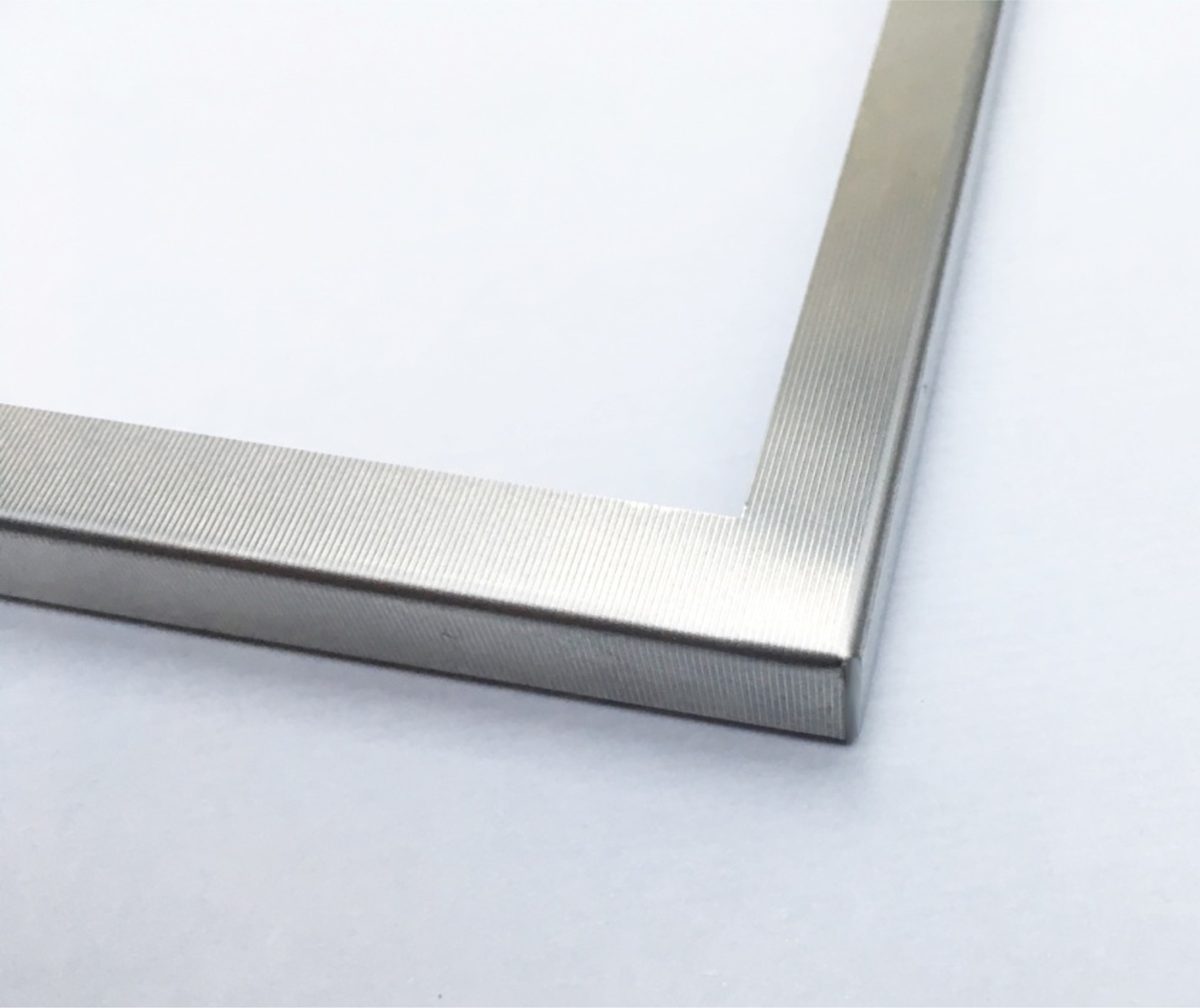

Sheet Metal

Seipo differentiates the metal forming with some unique processes:

Chemical etching for metal from 0.02-1.5mm with the highest precision tolerance up to 0.01mm. Paired with precision laser welding, we make a fully enclosed seamless speaker grill for extreme audio quality.

Tight tolerance

Stamping special: deep drawn with no seam. Tolerance +/- 0.015 mm

Precision

High-Precision Stamping: To satisfy the modern clean design, Seipo has developed high-precision stamping equipment with astonishing pressure to make zero distortion during fabrication.

The final geometry and cosmetic finishing match the beauty of the CNC part at a fraction of the cost.