SPEED and QUALITY are top priorities in Seipo’s operation. To achieve them, we actively work with our customers very early in our process. We also involve suppliers from DFM, mold flow simulation, and prototyping to minimize risks and save valuable time in the whole process. We conduct FAIR, PPAP, CP/CPK capacity study and collaborate with customers in each stage from FA trail, DVT, PVT to MA to ensure quality and stability.

Special

Blazing Fast

30% shorter than standard tooling lead time

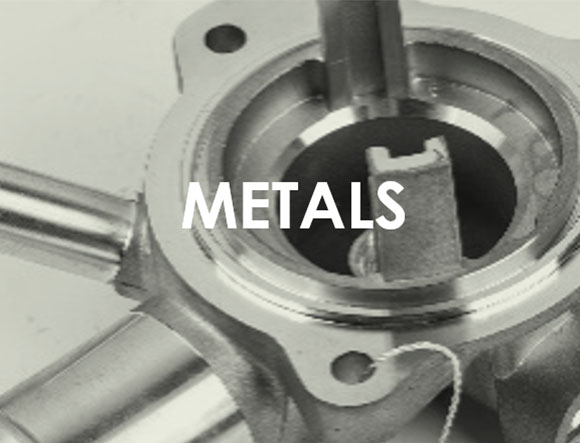

Die casting: up to 2000-ton press

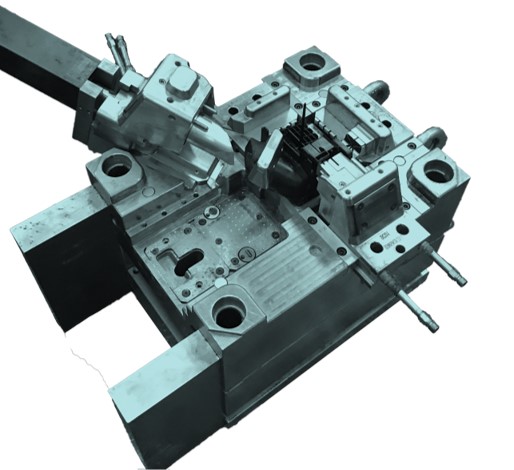

Injection molding: 3500-ton press

Metal stamping: 600-ton press

Most Flexible

Pilot run to mass production

We leverage different processes in realizing budgetary small run to large quantity mass production.

Easiest communication

30% shorter than standard tooling lead time

USA and China technical teams are full time available for project Q&A.

Logistics support for on time delivery.

Peace of mind

Peace of mind

Seipo is committed to meeting the needs of our customers by focusing on consistently delivering high-quality reliable products.

Seipo has established procedures to comply with applicable federal and state laws, and applicable industry standards such as ISO 9001; ISO 13485; FDA, and CCECS/China

ISO 9001, ISO TS16949, FDA certificate

Seipo is committed to meeting the needs of our customers by focusing on consistently delivering high-quality reliable products.

Seipo has established procedures to comply with applicable federal and state laws, and applicable industry standards such as ISO 9001; ISO 13485; FDA, and CCECS/China

ISO 9001, ISO TS16949, FDA certificate

https://seipo.com/wp-content/uploads/2022/01/P3_mold-flow-1.mp4

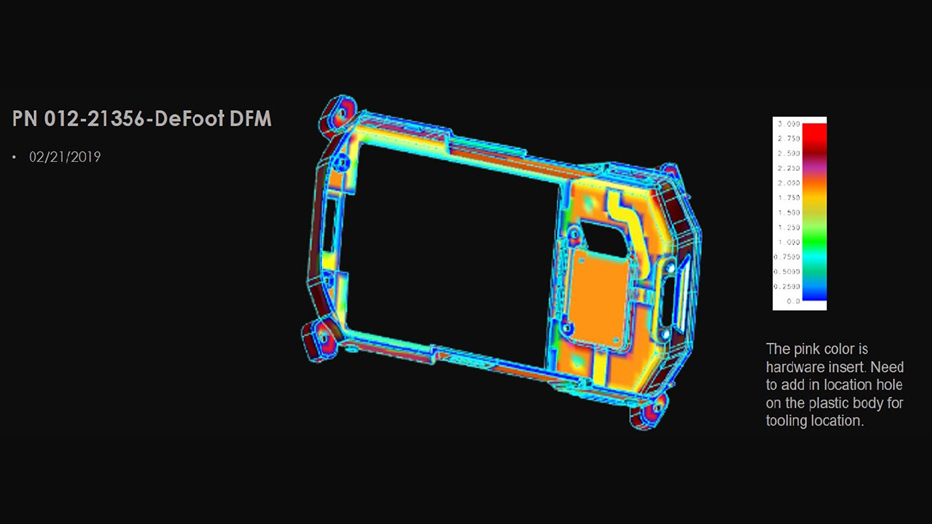

Engaging with Seipo in your product development brings extra reassurance for the final success of your project.

- Complimentary DFM analysis at RFQ

- Mold flow studies

- Complimentary design modification for DFM

- Prompt NCR solution for quality issue.

Engaging with Seipo in your product development brings extra reassurance for the final success of your project.

- Complimentary DFM analysis at RFQ

- Mold flow studies

- Complimentary design modification for DFM

- Prompt NCR solution for quality issue.

Advanced facilities

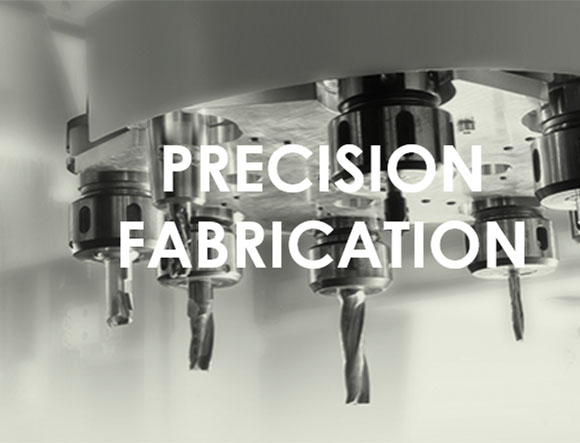

Equipment and process

Super Size Die Casting machine

Latest 4 & 5-axis CNC centers

Stamping and forming

Injection molding machine

EDM and Grinding

Painting & Coating lines

Offers

All inclusive